We discuss the following topics in this blog:

- Are the current networks future-ready?

- Faster Rollouts with Bend Insensitive Optical Fibre

- MFD Mismatch – A Challenge for Installers

- The world’s first legacy network compatible G.657.A2 Fibre

In addition to these topics, we shall also be answering the following FAQs:

- What is an Optical Fibre Cable?

- What is WiFi?

Contents

Are the Current Networks Future-Ready?

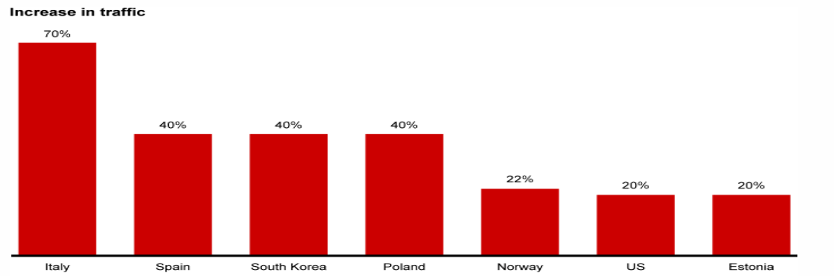

Exponential growth in internet data is inevitable due to the continuous advent of new use cases. Every year, millions of kilometres of optical fibre get added to the network to keep up with the pace of growing demand. Still, during the outbreak of Covid-19, internet users in many countries experienced as much as a 30% drop in 4G LTE experience. Various OTT platforms had to downgrade the streaming quality to handle the surge in demand. This highlights the fact that the networks of today still have a long way to go, so as to make them future-ready.

What is the Future of Digital Networks?

Faster Rollouts with Bend Insensitive Optical Fibre

The latest trends of data traffic growth and introduction of various use cases point towards a new converged network. These networks would be denser because of the multiplication of access layer endpoints. Also, they would require deep fiberization to provide better performance at a faster pace and optimum cost.

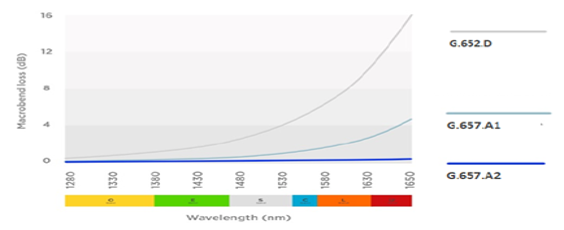

Better Network Performance:With the increasing geographical spread of optical fibre networks, fibre is going to connect a greater number of buildings and households. Various factors like macro and micro bends, splice loss and optical fibre attenuation lead to optical losses across the network. Legacy networks, which are mainly built using G.652.D fibres will have higher losses as the operating wavelength increases and optical fibre gets routed through tighter bends and smaller ducts. With the deployment of bend-insensitive fibres, bend losses of the network can be reduced drastically.

Improved TCO: Superior bend-insensitive performance results in an improved power budget, making the network resilient to accidental bends and cuts hence increasing the network’s life by many years. Increased power budget can also help an operator increase its geographical reach. Thus, bend-insensitive fibre reduces network capital and operational expenses.

MFD Mismatch – A Challenge for Installers

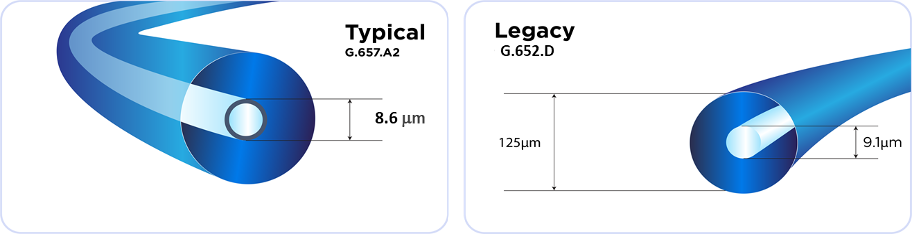

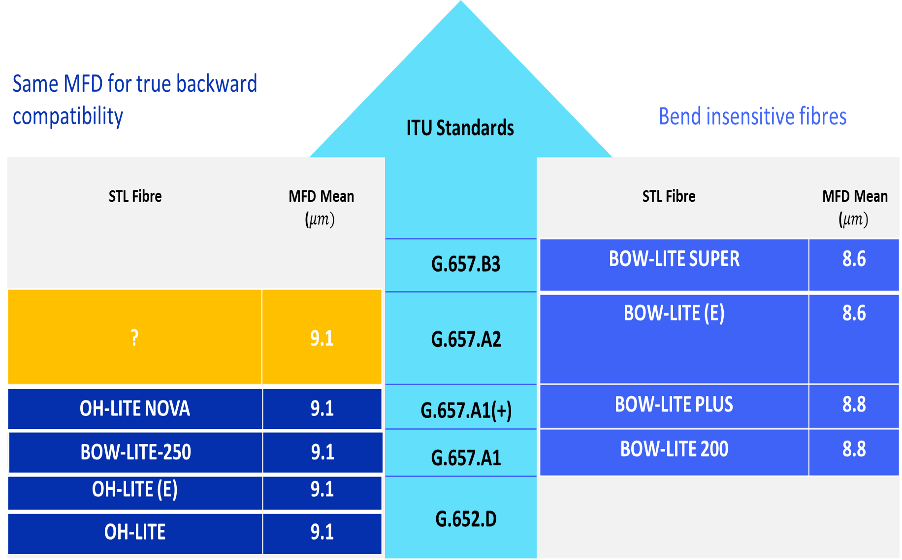

Deploying bend-insensitive optical fibre which adhere to G.657.A1 or A2 standards does not guarantee the best performance. When splicing the bend-insensitive fibre and fibre present in legacy networks (primarily G.652.D), Installer’s face another serious issue because of mode field diameter (MFD) mismatch.

MFD mismatch results in increased splice loss, splicing G.652.D and G.657.A2 fibre. Here optical power loss management also requires specialized tools such as calibrated laser source and power meter and a highly skilled technician at each end of the network.

Low fusion splice between G.652.D and G.657.A2 can be easily achieved, but in this case, the correct measurement and interpretation of the OTDR reading is a difficult task and can also create confusion while qualifying a link as ready to use. The issue arises because the OTDR results vary depending on the direction you measure it, resulting in an OTDR gain or loss error. Overall, this results in time being wasted to rectify the apparent bad splice. This reduced the first-time right rate and increases the time to deploy the network.

While ITU standards focus mainly on the bend insensitivity but maintaining backward compatibility is an industry imperative. Today, the Operators need legacy network compatible ITU G.657.A2 optical fibre.

Stellar™ Fibre – The world’s first legacy network compatible G.657.A2 Fibre

Leveraging our experience of working closely with leading Telcos across the industry and our expertise in network deployment, we created Stellar™, the world’s 1st G.657.A2 macro bend-insensitive optical fibre which is compatible with legacy networks comprising of G.657.A1 and G.652. D fibre.

Future-ready Stellar™ helps build the network faster and efficient, saving both time and money. It is the ideal choice for next-gen PON technologies, delivering 40 Gigabits per wavelength up to 1625 nm on a single optical fibre.

Stellar™ – Bends like Magic

Better Network Performance: The macro bend losses of Stellar™ adhere to the ITU-T G.657.A2 standards, even at higher wavelengths and 7.5mm bend radius. Superior macro bend performance results in compact splice box and smaller manholes.

Improved TCO: Stellar™ increases the network’s life by as much as 10 years. Lower macro bend losses and best in class attenuation results in a more resilient network, that can accommodate a greater number of repairs arising out of accidental cuts and bends.

Stellar™ – Blends like Magic

Faster Rollouts: Stellar’s innovative design with MFD of 9.1 µm ensures seamless splicing with legacy networks resulting in faster network roll-out and minimal splice loss, even with semi-skilled installers.

Interested in building the future of digital networks with Stellar™ fibre to ensure future readiness, better network performance at a faster pace and optimum cost, contact your STL sales representative or visit https://www.stl.tech/connectivity-solution/optical-fibre/

FAQs

What is an Optical Fibre Cable?

An optical fibre cable is a cable type that has a few to hundreds of optical fibres bundled together within a protective plastic coating. They help carry digital data in the form of light pulses across large distances at faster speeds. For this, they need to be installed or deployed either underground or aerially. Standalone fibres cannot be buried or hanged so fibres are bunched together as cables for the transmission of data.

This is done to protect the fibre from stress, moisture, temperature changes and other externalities. There are three main components of a optical fibre cable, core (It carries the light and is made of pure silicon dioxide (SiO2) with dopants such as germania, phosphorous pentoxide, or alumina to raise the refractive index; Typical glass cores range from as small as 3.7um up to 200um), Cladding (Cladding surrounds the core and has a lower refractive index than the core, it is also made from the same material as the core; 1% refractive index difference is maintained between the core and cladding; Two commonly used diameters are 125µm and 140µm) and Coating (Protective layer that absorbs shocks, physical damage and moisture; The outside diameter of the coating is typically either 250µm or 500µm; Commonly used material for coatings are acrylate,Silicone, carbon, and polyimide).

An optical fibre cable is made up of the following components: Optical fibres – ranging from one to many. Buffer tubes (with different settings), for protection and cushioning of the fibre. Water protection in the tubes – wet or dry. A central strength member (CSM) is the backbone of all cables. Armoured tapes for stranding to bunch the buffer tubes and strength members together. Sheathing or final covering to provide further protection.

The five main reasons that make this technology innovation disruptive are fast communication speed, infinite bandwidth & capacity, low interference, high tensile strength and secure communication. The major usescases of optical fibre cables include intenet connectivity, computer networking, surgery & dentistry, automotive industry, telephony, lighting & decorations, mechanical inspections, cable television, military applications and space.

What is WiFi?

Put simply, WiFi is a technology that uses radio waves to create a wireless network through which devices like mobile phones, computers, printers, etc., connect to the internet. A wireless router is needed to establish a WiFi hotspot that people in its vicinity may use to access internet services. You’re sure to have encountered such a WiFi hotspot in houses, offices, restaurants, etc.

To get a little more technical, WiFi works by enabling a Wireless Local Area Network or WLAN that allows devices connected to it to exchange signals with the internet via a router. The frequencies of these signals are either 2.4 GHz or 5 GHz bandwidths. These frequencies are much higher than those transmitted to or by radios, mobile phones, and televisions since WiFi signals need to carry significantly higher amounts of data. The networking standards are variants of 802.11, of which there are several (802.11a, 802.11b, 801.11g, etc.).