Fiber optic networks have gained significant popularity in recent years as the demand for increased network speed has been consistently rising across the planet. Due to its high-speed data transmission with low attenuation, particularly for long-distance deployments, fiber optic networks are widely accepted in high-bandwidth applications. This includes mission-critical applications such as surveillance camera systems. Single-mode optical fiber is used extensively for fiber optic communication today as it has virtually unlimited bandwidth capacity.

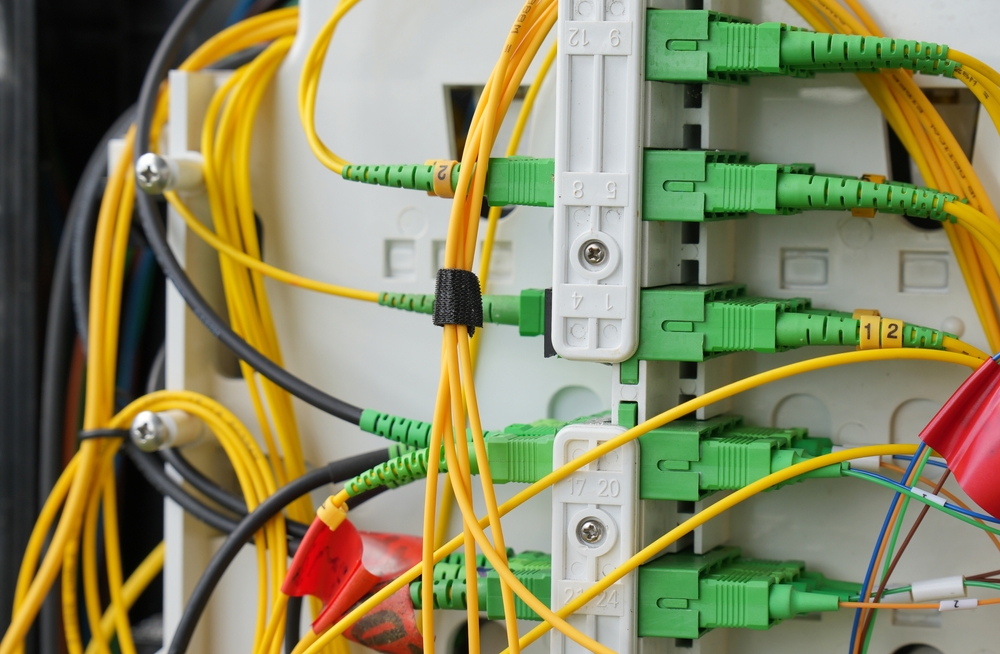

As the number of connected devices increases worldwide, the management and distribution of fiber cables become more complex. They can get tangled easily if they are not properly maintained. Moreover, they are also quite susceptible to oxidation owing to long-term exposure to the outdoor environment. A Fiber Termination Box (FTB) was essentially developed to address this issue. It helps protect fragile fiber terminals and facilitates a simple system for managing both outgoing and incoming cables.

Contents

Fiber Termination Box: A brief overview

Fiber Termination Box (FTB) or Optical Terminal Box (OTB) is a distribution box specially designed for fiber cable management in FTTH applications. Its core use is to terminate fiber optic cables and connect the cable’s core and pigtail. A fiber pigtail is a short, single, tight-buffered optical fiber that has an optical connector pre-installed on one end and a length of exposed fiber at the other. One of these ends is stripped and fusion spliced to a single fiber. On the other hand, the other end connects the optical transceiver modules or fiber optic converter to form an optical data transmission path. The pigtail connects the fiber cable through couplers or adapters in the box and then connects to the fiber patch cord when used in the termination box.

The fiber termination box is an important aspect of ADSS Cable installation. It provides a budget-friendly means for systematically handling expansive quantities of fiber cables, with higher flexibility and lower expenses. The number of fiber cores in the FTB tends to vary based on distinctive manufacturers. The fiber core may range from 2 to 96 ports, based on real-life applications.

A typical fiber termination box comprises three parts, the fiber connector protection element, internal components, and the housing. Its internal components are typically encapsulated in an IP-rated housing made of impact-resistant and sturdy materials that can protect against damages caused during operation and placement. For long-term outdoor deployments, it becomes important for FTB components to be dustproof and have good resistance to corrosive elements. Its housing should be easy to open and have provisions for a lock to prevent potential tapping.

The internal components of a fiber termination box include fixtures, a fixed fiber tray, as well as a supporting frame. This supporting frame is the main body of the internal structure. To maintain fibers in an organized manner, the fiber tray is used for mounting LC/ST-type fiber adapters. Based on distinctive requirements, the splice tray is sometimes located within the termination box to accommodate fused fibers. The fixtures are subsequently used for fixing fiber pigtails or optical cables for improved organization. The fiber connector is generally shielded by a head-shrinkable clip or tube for improved protection.

Protection and management of fiber optic cables

While fiber optic cables have many advantages, fragility is one of their biggest limitations. Generally made of glass, fiber optic cables are much lighter and thinner than metallic wiring, making them widely susceptible to damage. Radiation or exposure to chemicals can damage a fiber optic network. Its fragile cables can be cut easily during building rewiring or renovations. Fiber cables also have a limited bend radius, thereby complicating the prospect of laying them around corners. Too much bending built into the system may cause breakage or signal attenuation. Hence, extra protection is required to ensure that multicore or single-mode optical fiber works properly. FTB integrates the storage, management, splicing, and termination of fiber optic cables in a single unit. It is designed to be managed, maintained, and installed with ease. With a compact rack or wall mounting design, the Fiber Termination Box is a space-saving solution for fiber optic installation, especially when it is not feasible to have large terminal hubs.

Diverse types of FTBs

Wall-mounted and Rack-mounted

Fiber Termination Boxes can be categorized into rack-mounted and wall-mounted boxes based on their designs. The latter is generally sealed and hangs on the wall, while the former has a rear and front door with a side rail attached directly to the rack of the server.

Wall-mounted FTB is largely meant for direct connections. Procedures like fusion, splicing, and termination have to be done prior to the installation of an FTB. A wall-mounted fiber termination box is well-suited for applications like teleconferencing, building entrance terminals, and so on. These FTBs can be further subcategorized into outdoor and indoor boxes.

On the other hand, rack-mounted enclosures are ideal for interconnect or cross-connect architecture. Such FTBs are ideal for building interfaces between the transmission device and external plant cable, with enough space for management, termination, distribution, and fusion. Rack-mounted FTBs, however, are only for indoor deployments.

Indoor and Outdoor

Based on their applications in varied settings, FTBs can be divided into the categories of outdoor and indoor termination boxes. The key difference between them will be the materials used for manufacturing. The materials used in a unit must be comparable to those used in other elements, and even the cable/pigtail sheaths. In case an FTB is meant for outdoor deployment, its chemical and physical properties have to be stable enough with good resistance to water and dust. The melting temperature of the materials also must not be less than 120°C. The FTB components must operate over an expansive temperature range of at least -25°C to 45°C to survive major temperature fluctuations. Its outer casing is typically well-sealed to protect the inner components from damage and has high impact resistance. The indoor FTB, on the other hand, is known to be the transition point between horizontal and upstream cables. They are commonly used as a storage location for fiber distribution and termination in more of a controlled setting and hence do not have any special requirements in terms of the materials. To select the perfect fiber termination box for your network, you need to assess your requirements competently and opt for the option that effectively aligns with your needs. FTBs can be found in a variety of materials, shapes, and sizes. You need to take into account the number of fibers used and space available, among other things, to identify the one that would work the best for your assembly.