The networking demand worldwide is rapidly growing. Even though single and multi-mode fibers are available. Single-mode optical fibers may help curb this growing demand. That is because they have a high capacity to transfer data. There are many single-mode fiber types. This article will tell you about G657A2 single-mode fiber.

Contents

What Are G657A2 Cables?

G657A2, a subcategory of G657A, is a single-mode optical fiber with high bending performance. Its bending performance is higher than G652 single-mode fiber optic cable; however, it is entirely compliant. Additionally, its bend radius is lesser than that of the G657A1 fibers, another subcategory of G657A fiber optic cables.

Features And Benefits Of G657A2 Cables

The loss due to visible bending, macro bending loss, is lower in G657A2 fiber specification compared to G652D fibers. Therefore, you can use these optic fibers throughout the access networks.

- You can use G657A2 as a single mode os2 or os1 fiber.

- These fibers can carry the light of wavelengths between 1260 nm to 1625 nm ( i.e., bands O-, E-, S-, C-, and L-).

- Another benefit of G657A2 cables is that you can use them with G652D cables as their transmission and interconnection properties are the same. That also means that you can use G657A2 wherever you require G652D.

- The design radius ( the minimum radius through which you can bend these fibers) of these fibers is 7.5 mm. So using these fibers, you can make a ring with a radius of 7.5 mm without damaging it. So you can place these fibers in tight corners.

What Is The Difference Between G657A1 And G657A2?

Both the cables G657A1 and G657A2 are subcategories of G657A cables. Therefore, both of them are compatible with G652D fiber optic cable. However, their macro bending losses and minimum bending radius vary.

Minimum Bending Radius

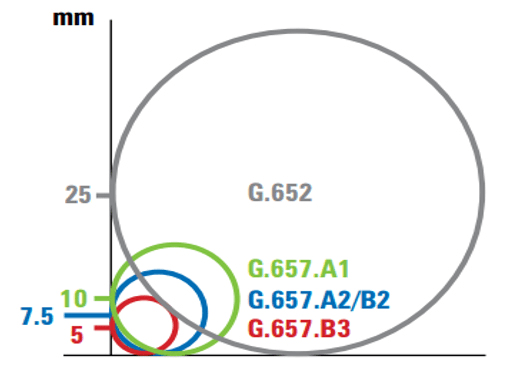

The minimum bending radius of G657A1 is 10 mm, and that of G657A2 is 7.5 mm. The following diagram shows the difference in bend radius of different optical fibers.

Source: Bend Radius

MacroBending Loss

Macro bending losses are radiation losses in an optical fiber that occurs when you bend the fiber. The loss depends on the bend radius of the fiber cable. The macro bending loss also depends on the wavelength of the light that passes through it.

Suppose the wavelength of the light through the cables is the same. Then the only parameter that affects the macro bending loss is the bend radius. According to ITU-T, the macro bending loss of G657A2 is lower than that of G657A1. You can see the following table for the exact values.

|

| ITU-T G657A1 | ITU-T G657A2 | |||

| Radius | 15 | 10 | 15 | 10 | 7.5 |

| No. of Turns | 10 | 1 | 10 | 1 | 1 |

| Max at 1550 nm | 0.25 | 0.75 | 0.03 | 0.1 | 0.5 |

| Max at 1625 nm | 1.0 | 1.5 | 0.1 | 0.2 | 1.0 |

Stls G657A2 Bend-Insensitive Optical Fiber Cable

Celesta is the name of the G657A2 bend-insensitive optical fiber cable manufactured by STL. It is a small and dense optical fiber ribbon cable. The cable has a collapsible design and is slimmer than loose tube cables. You can blow this cable inside a 20 mm duct. Its soothing and non-preferential bending will allow you to blow this cable quicker into a fiber optic duct. Additionally, its multiple peripheral strength members will provide you with crash protection. It is also resistant to rodents. The optical fiber also has a gel-free water blocking design.

Source: STLs Celesta

FAQs

What is A2 fiber?

A2 is a subcategory of G657A fibers compliant with G652D optical fibers. Its minimum bend radius is 7.5 mm; you can bend that fiber into a ring with a radius of 7.5 mm. And at that radius, its macro bending losses at 1550 nm and 1625 nm are 0.03 and 0.1, respectively.

What is bend-insensitive fiber?

A bend-insensitive refers to the low minimum bend radius of these fibers. For example, you can call G657A2 “bend insensitive fibers” as you can bend these into smaller rings than G652D. The bend radius of G652D fibers is 30 mm, and that of G657A2 is about 7.5 mm. G657B3 is another example of bend-insensitive fiber. It is more bend-insensitive than G657A2; its bend radius is only 5 mm. Both single mode and multi-mode fiber can be bent insensitive.

Does bend-insensitive fiber reduce macrobending losses?

Yes, bend-insensitive fibers reduce macro bending losses. For example, G657A1 is less bend-insensitive than G657A2. And according to ITU-T, G657A1 has a loss of 0.75 at a bend radius of 10 mm. However, the G657A2 has a macro bending loss of only 0.1. Further, at 15 mm, the bending loss reduces to 0.03. That means at 30 mm bending loss, it will be negligible for G657A2. But the G652 fibers have a bending loss of 0.1 at 30 mm.

Can I bend fiber to reduce macrobending losses?

No, bending the fiber does not reduce macro bending losses. This is true for single-mode fiber and multi-mode fiber. Moreover, if you do that, the loss will increase. They are inherent to the optical fiber itself. However, it may depend on the wavelength of the light and the bend radius. For example, the bend radius of G657A2 at 1550 nm wavelength and 10 mm radius is 0.1.

How are A2 fibers better than A1 fibers?

A2 fibers are better than A1 fibers as A2 fibers are more bend insensitive. Due to the low bend radius of G657A2 fibers, you can use them in tighter spaces. They also have a low macrobending loss. That means the radiation loss will be lower with G657A2 fibers than that of G657A1.