The Telecom industry is witnessing significant shifts in technology and capital expenditure.

The Telecommunication industry is developing at a dizzying rate. As technologies continue to be a part of our daily lives, their capabilities evolve rapidly. To touch upon a few newsmakers, the fifth generation of wireless cellular connections is already at the doorstep and is promising a new era of technology. As demand for digital services skyrockets, companies like Amazon, Microsoft, and Google are installing massive data centers that are scalable, efficient, secure, and packed with state-of-the-art technology. Simultaneously, the rapid expansion of the Internet of Things (IoT) shows no sign of slowing down as more and more enterprises embrace IoT. Furthermore, the burgeoning demand for virtualisation is pushing software disrupting networks into the spotlight.

Contents

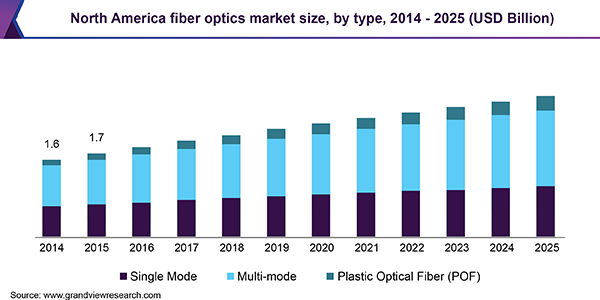

Unabated Growth in Demand for Optical Fiber

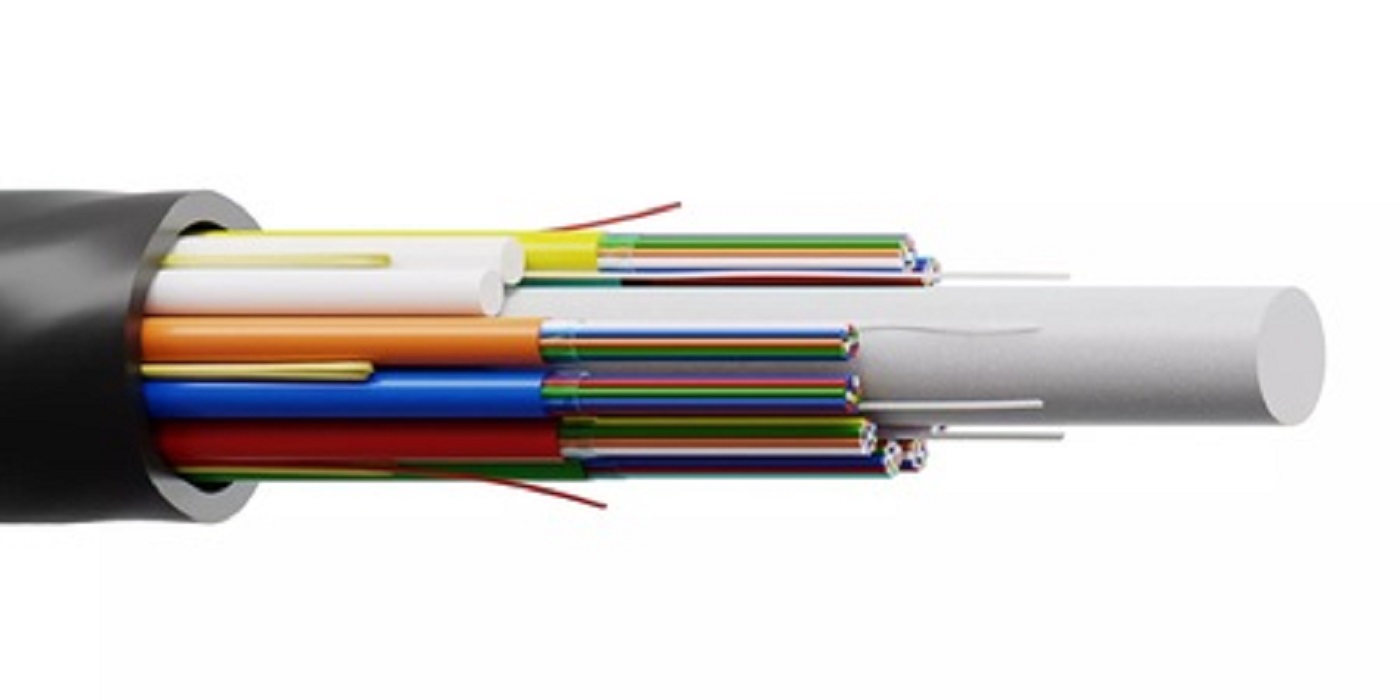

Optical fiber systems transmit voice, data, and media through thin and transparent fiber strands to distances covering from a few meters to several kilometers at a blazing speed. Currently, the technology is extensively used in telecommunication industries, healthcare, environmental monitoring, the defense sector, and transmitting radio signals. In 2019, the global fiber optic cable market was valued at USD 7,578.1 million, and by 2025, it’s expected to reach USD 16,390.6 million, reporting a CAGR of 14. The key factor driving this market is the growing demand for internet services. The digitally-literate population is starving for high bandwidth communication and data transmission services. When it comes to bandwidth, optical fiber beats every other currently available technology hands-down. As a result, optical fiber cable deployment has outpaced the growth of the world economy by five times. The speed of deployment has also shrunk drastically. What previously took 38 years to deploy 1Bn fkm cable, now takes less than two years.

As a blessing in disguise, the COVID-19 pandemic accelerated the demand for optical fibers. When over 1.2 billion children were out of the classroom, e-learning matured; and with that came the phenomenal rise of digital platforms like Zoom, Google Classroom, Meet, and many more. Whether studying or working from home, everybody needs uninterrupted and high-quality connectivity. As online viewing doubled during lockdowns, streaming services like Netflix saw 16 million new sign-ups. All of this had cumulative effects on the demand for data, and it seems that nearly ten times the fiber deployment is required at three times the speed.

Micro Cabling Technologies

High-speed networks are connecting the world every day. And when it comes to speed and bandwidth, micro cables offer exceptional reliability, performance, and value for investment.

Micro cables are minute loose-tube cables that are 70 percent lighter and 50 percent smaller than standard loose tube cables. Again, though, the miniaturisation doesn’t impact the performance at all. In addition, the buffer tube diameter is reduced to enable high per-cable fiber density. For added protection, it’s recommended that micro cables be deployed only in micro ducts.

The primary features of Micro cables are:

- Thinner jacket

- Smaller tubes

- 200 um fiber

- More fibers per tube

- IBR ribbon

Benefits of Micro Cables

Higher fiber density of Micro cables increases efficiency. Micro cables are lighter and smaller, which makes transportation reels easy to move. Cable handling is improved as smaller crews can take care of the installation.

To summarise the benefits, Micro Cables are:

- Blow optimised

- Reduced cable diameter

- Super lightweight

- Easy to handle

- Smaller drum efficient logistics

- Reduced risk of cable damage

- Highly scalable and flexible.

How Can We Build Denser Networks Faster?

Micro cables are denser – they can hold up to four times more fiber. Where a traditional 72F duct has a diameter of 20mm to 25 mm, a maximum duct-space-optimised 288F next-generation micro cable is just 10mm to 12mm in diameter. Urban deployments of Micro cables are challenging, and that’s where Microtrenching shines. Micro trenching is an installation method for underground ducts that takes less time and is minimally invasive. It’s especially suited for compact areas such as roadways, curbs, sidewalks, or under concrete blocks. In addition, for better installation capacity, existing duct spaces can be augmented.

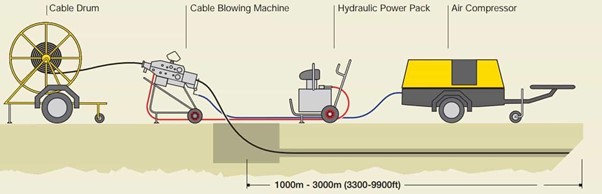

To add reliability and reduce risk to service continuity, multi-way ducts can be used to segregate services. Additionally, faster installation is achieved by using the blowing method. It improves installation efficiency, and saves workforce and installation time over the traditional pulling method.

However, the challenge is that the specialised equipment needs proper handling and a knowledgeable crew. Furthermore, longer splice time can also eat into your deployment schedule.

Blow vs. Pull Installation

In the Pull method, the micro cable is attached to a pre-installed tape, and then pulled mechanically or manually from the other end. Potential cable damage can occur due to friction as the micro cable moves through the duct. Pulling fiber is generally recommended for short distances up to a few hundred feet. It’s easier to get a familiar crew though, as this is a traditional installation method.

Meanwhile, in the blowing or jetting installation method, a machine is used to float the micro cable through the duct using highly pressurised air. It’s great for long-distance deployment that can go up thousands of feet. In addition, it saves considerably on labour and material costs as fewer handholes and splice points are used.

Pulling requires 2.5 times more effort and six times more time than the blowing method. So if we blow install micro cables in a 7-way microduct, it’s a recipe for a much denser and faster network.

Success Story

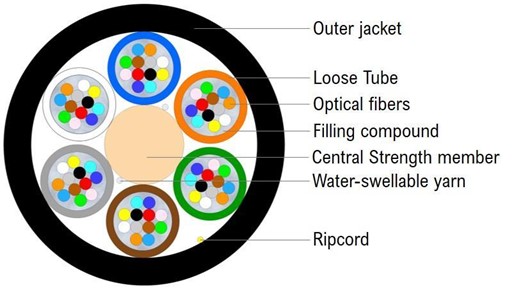

576F Next-Gen Micro Lite Cable in the Philippines –

The world’s slimmest 576F cable was installed in the Philippines. The Micro loose tube with fibers and gel has a central strength member. The future-ready fiber has water swelling yarn and has a 10.3 mm overall diameter with 200μ fiber. It was installed in an 18/14 duct. The project was handled with great ease and underwent a quicker installation. Lesser spool weight and facility to over-blow in existing ducts ensured efficient logistics and asset utilisation. Two times more fibers were installed in a cost-effective way. Even after blowing 1500 m, a blowing speed of 85 m/min was achieved. The final results of the initial blow target that was achieved were better than expected.